Next generation recycling

for composites

At Composite Recycling, our approach to the recycling of composites features innovative new technology and services calibrated to each customer’s specific needs.

Our Solution for Sustainable FRP Recycling

Bringing circularity to composite waste

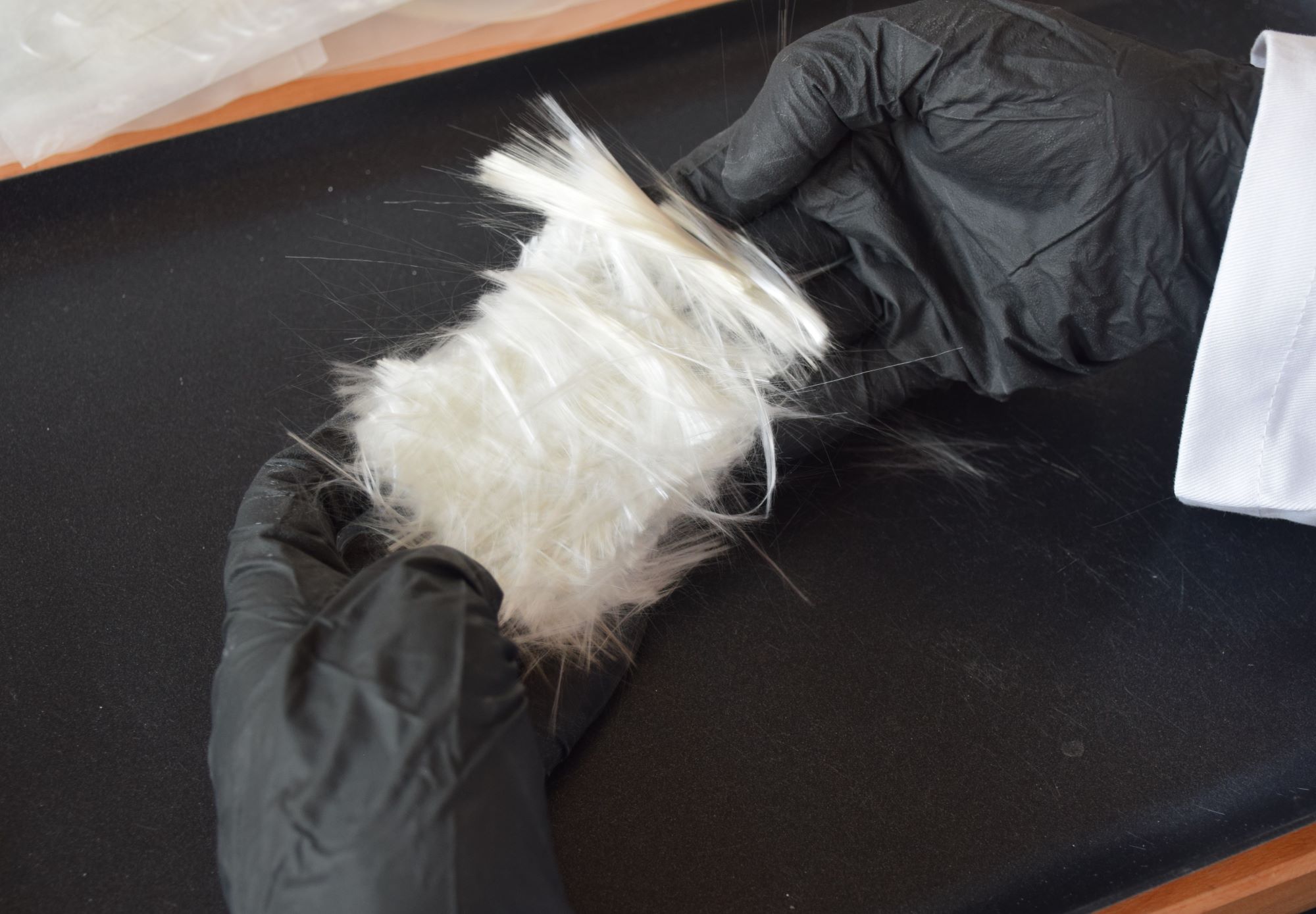

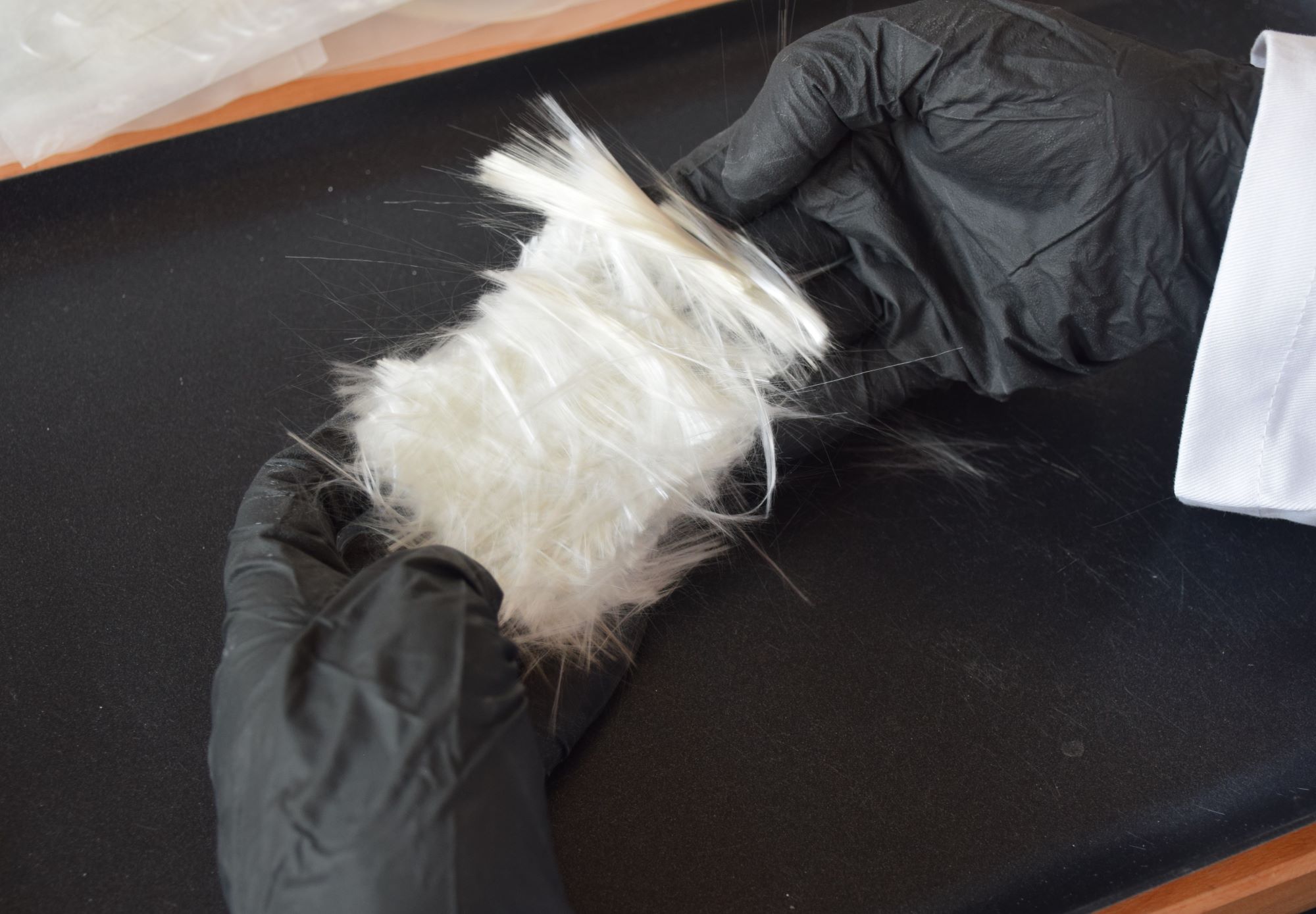

Thermolysis is a technique in which heat is applied in an oxygen-free environment to separate the fibres from the resin found in fibre-reinforced plastics (FRP) like fibreglass and carbon fibre.

At Composite Recycling we recycle FRP waste with a proprietary static thermolysis process and post-treatment, which together maximize the quality, consistency and reusability of the process outputs (fibres, thermolysis oil and gas).

Our mobile recycling technology

Our thermolysis treatment units are designed to fit into 30” containers. This means we can deploy our reactors to sites adjacent to waste stockpiles, reducing the costs, complex logistics and carbon emissions of transporting bulky discarded waste materials

It also enables temporary deployments – such as for surveying waste streams in a given region, or to treat decommissioned blades at wind farms.

Calibrated to our clients’ needs

We carefully calibrate our reactors so that the reclaimed fibres and thermolysis oil meet the required specifications of our downstream manufacturing clients, who can then recombine them to make new composite materials, plastics, and resins – usually with no retooling needed.

Composite manufacturers can also call upon us for guidance when developing new composite products, to ensure a robust recycling solution is available at the product’s end-of-life.

Calibrated to our clients’ needs

We carefully calibrate our reactors so that the reclaimed fibres and thermolysis oil meet the required specifications of our downstream manufacturing clients, who can then recombine them to make new composite materials, plastics, and resins – usually with no retooling needed.

Composite manufacturers can also call upon us for guidance when developing new composite products, to ensure a robust recycling solution is available at the product’s end-of-life.

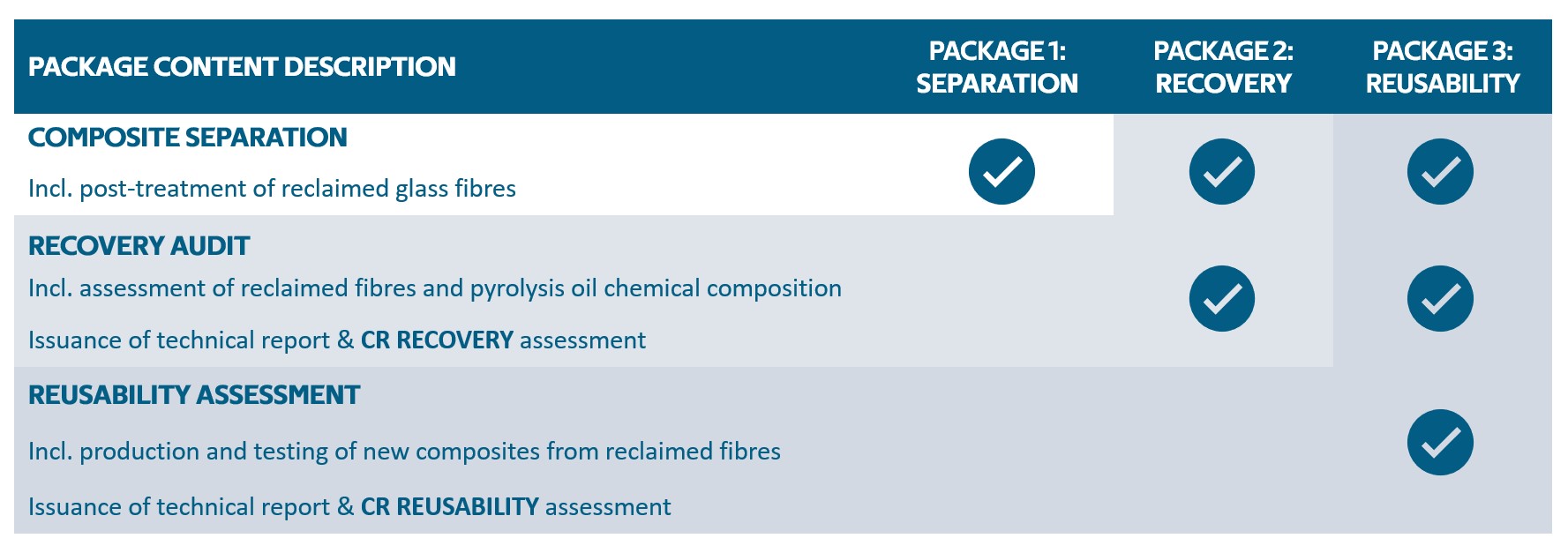

Start your recycling journey with us.

As a first step, submit your waste materials to determine the recoverability and evaluate the quality of the outputs.

The test results will also enable you to demonstrate the recyclability potential of your products to internal and external stakeholders, and to start formulating real end-of-life solutions.

Client Testing

We offer a range of tests to suit our customers’ needs, and have already performed over 450 pyrolysis tests for clients in the marine, aerospace, automobile, sporting goods, chemical and other industries.

Get in touch and we can help you determine which is right for your organisation.

What makes our solution different and better?

“The judges decided to award the win to the Beneteau Group for its collaboration with Composite Recycling and Chomarat because it provides an answer to one of the largest issues of all – creating a viable second use option within the industry for the millions of GRP hulls manufactured in the last 60 years.”

IBI METSTRADE 2023 Boat Builder Awards Judges’ summary